I love tiles, I really do. I love to touch them. If they have texture, all the better. I could go to Ann Sacks and pull up a stool and hangout in that store for hours. Can I afford her? No, I can’t, not even a sample. Hence me saying hangout, not shop.

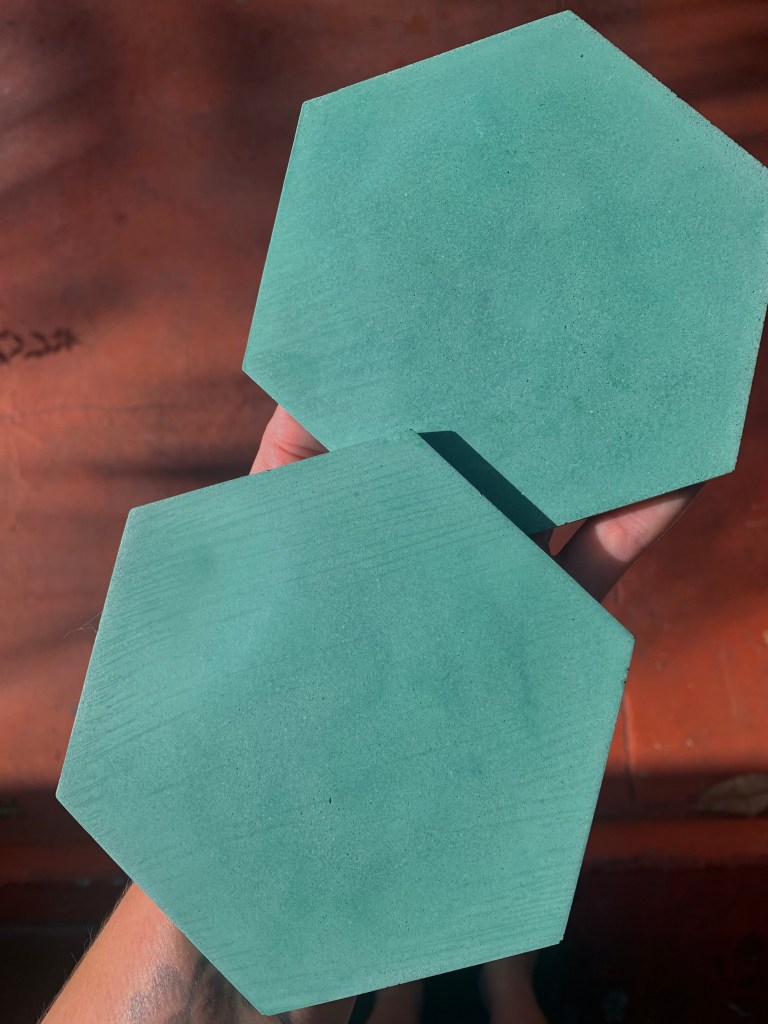

My first tile project is Ms. Hexagon Green. It took me many samples to get to a color I was happy with. I used different cements, different ratios of color, adding dye to the water first or adding dye to the cement. I finally settled with white Z Counterform Cement. I found a green cement dye that matches the color I want. You have to keep in mind, no matter how hard you try, you will NEVER get the exact same color as the batch before. But that’s what I want, variations of green. Green, green and more green. I bought hexagon molds from AliExpress. Twenty of them. I mix enough for the 20 molds in one batch, the drying time is forgiving so I can take my time. I demold these after 24 hours, they are still wet but dry enough to take them out and do another batch. If you’ve been following along and familiar with the pink bathroom, the green tiles are going there.

Then the floral white tiles – for Georgia also. I saw this tile in a tile box store and bought one and stared at it for a while. I decided to make a copy of this tile, which was glazed in grey, typically I would love this but I wanted it white. I made a copy using a 2 part silicone mold making kit and bought a framing/mold jig. Voila….instant mold. I made 4 to speed up the process. Now I make 4 tiles at a time……in reality, I will need to make at least another 4 or 10 molds to finish before I’m 60 years old. I use the same white Z Counterform Cement. The tiles are so pretty. The white tiles are for the blue bathroom.

For the front entry of the house in Miami, I have added the Stars and Crosses (sorry, no photos for these) from Zellige. Zellige tiles are beautiful and super sexy…..I just can’t afford them so of course I duped them. I use a QuickCrete cement with this one. I made the mold the same way – the cement is different. This starts to harden in minutes so I have to work fast, really fast – there is no time for mistakes. I mix a black dye to the cement with gloved hands rubbing it between my fingers to get the lumps out and to make sure the dry goods are blended well prior to adding water. I mix quickly and pour and literally watch it harden. I wash my bowl and stirrer before it hardens.

Now, with slow production and chipping away….I have tiles all over my damn house – stacks here, stacks there. Tiles curing, tiles that need to be sanded, tiles that need or have been sealed.

According to the blogs and posts that I have read, cement takes 28 days to cure. I have more than this between my batches so I’m good. I take my tiles batches at a time, sand them (with 220 grit) all in water to clean them up a little and have a little roughness on the top of the tile to adhere the sealer. The sealer is a 2 part liquid from the Z Concrete website.

Is homemade tile more cost effective? A bag of cement is about $80 plus shipping. Let’s say $100 with tax and shipping. The dye about $12 a pound bag, about $4 a piece for the mold and about $30 for the sealer. It is considerably cheaper but you have to be good at time management!! Just sayin’.

INSPIRATION FOR THE GREEN TILES: